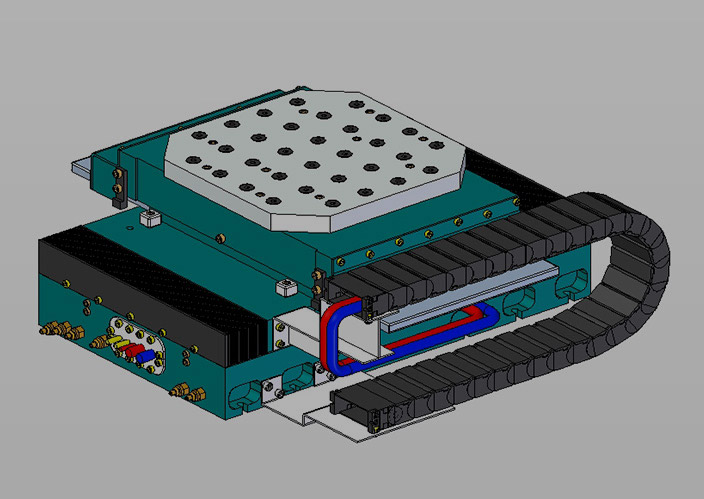

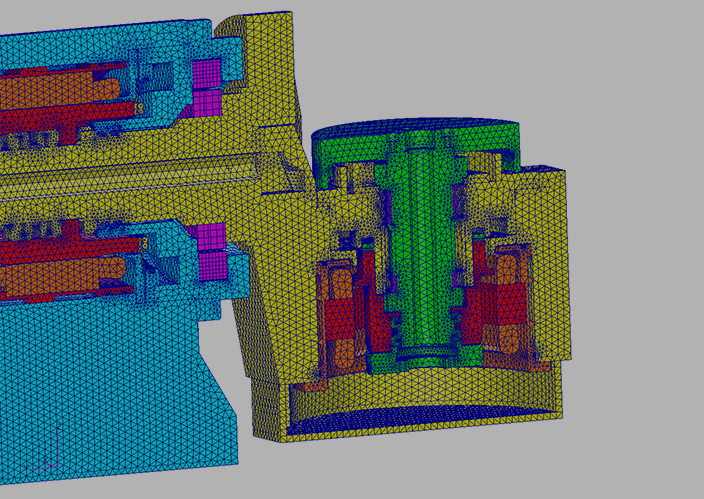

The good knowledge of calculation techniques and its flexible structure makes Ce.S.I. the ideal partner in innovative product projects. The company has got a good deal of experience in solid modelling as well as in kinematic and FEM structural simulation of machines and materials providing high quality and reliable solutions for innovative products development

- Static Analysis

- Stress Analysis

- Buckling Analysis

- Modal Analysis

- FRF and Transient analysis

- Mechatronic integrated simulation

- Thermal Analysis

- Sensitivity analysis and structural Optimisation

Ce.S.I. supports the customers with test and measuring capabilities, such as

- Measuring and analysing vibration problems (FFT, FRF, time history, ...)

- Experimental modal analysis

- Critical frequencies

- Modal shapes

- Modal damping

- Analysis of chatter

- Numerical-experimental models validation

Ce.S.I. can also integrate Probabilistic Design (also known as «Robust Design» or «Strength-Stress Analysis») within the conventional FEA approach. With this novel methodology input parameters for a FEA structural analysis are not considered as fixed values but can be assigned through a distribution. This allows predicting variations in design performance, but also it enables design for reliability of the structure.

In the PDS approach input parameters are random input variables and are characterized by their distribution type. In the same way the key output parameters are defined as random output variables. During the probabilistic analysis multiple loop are executed in order to compute the random output parameters as a set of function of input variables.

A correlation among inputs and outputs is established so that it is possible a sensitivity analysis, defining which input variables contribute the most to the scatter of an output parameter. Acting on the corresponding input it is possible to decrease the scatter of the result, increasing as consequence robustness.